Production bottlenecks are not always caused by lack of capacity. In many manufacturing plants, delays happen because teams work with incomplete data, manual planning, and disconnected systems. When inventory, production, quality, and maintenance operate in silos, even a small issue can slow down the entire operation.

This is where a manufacturing-focused ERP system changes the equation. By centralizing data and automating workflows, ERP helps manufacturers move from reactive firefighting to controlled, predictable execution.

This is where the right ERP integration makes a measurable difference. Not by adding another system, but by connecting everything into one structured workflow.

Why Production Bottlenecks Keep Showing Up in Manufacturing

Bottlenecks are often visibility problems, not capacity issues. Data silos created by separate systems (CRM for sales, standalone apps for inventory, Excel for production planning) lead to blind spots and profit leakage.

Discrepancies between system inventory counts and actual stock, leading to production halts and expensive rush shipping.

Lack of communication about raw material delays causes idle operators and stalled jobs.

Quality defects discovered late in the process due to a lack of integrated data, resulting in rework and missed shipments.

What Precision Manufacturing Looks Like with ERP

Precision in manufacturing does not mean complexity. It means clarity and control.

ERP enables precision manufacturing by shifting from reactive guesswork to proactive control, characterized by:

One System of Record

All departments access the same data, ensuring automatic schedule adjustments and eliminating information silos.

Standardized Workflows

Reliance on repeatable, automated processes rather than individual expertise, ensuring consistency and reducing errors.

Contextual Intelligence

System suggests solutions, like identifying affected orders when machines go down, enabling proactive problem-solving.

Enterprise-grade ERP for complex manufacturing

Cloud ERP for growing manufacturers

Integrated solution for Microsoft ecosystem

Ready to Eliminate Production Bottlenecks?

Discover how Hornet Technology’s ERP solutions can transform your manufacturing operations with real-time data, automated workflows, and predictive insights.

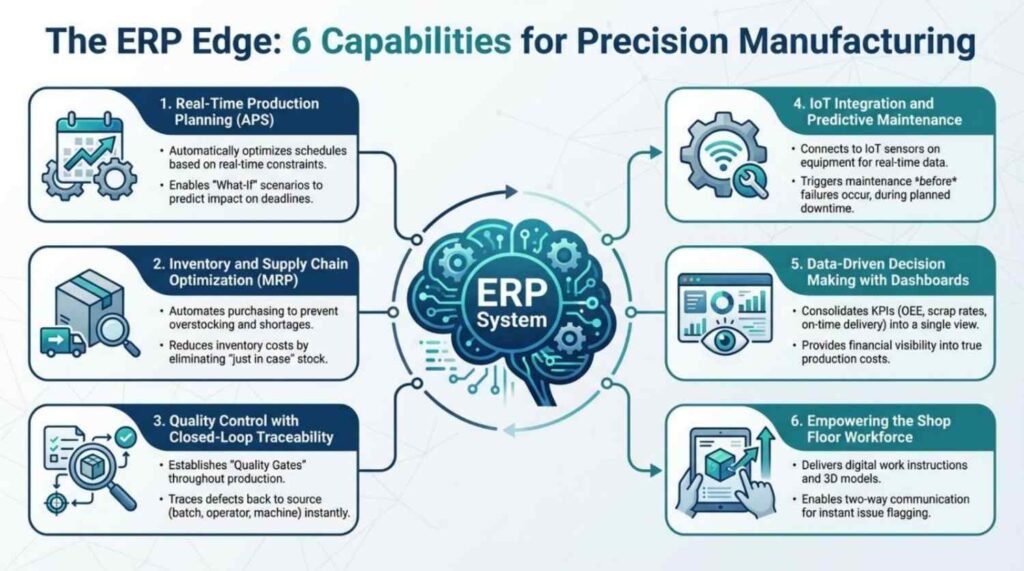

ERP Capabilities That Turn Bottlenecks into Predictable Output

- Real-time Planning

- Inventory Optimization

- Quality Control

- IoT & Predictive Medicine

- Data Dashboards

Real-time Production Planning and Scheduling

Manual scheduling often ignores real-world constraints. ERP replaces this with dynamic planning.

- Production schedules update automatically based on material availability, machine capacity, and labor.

- Changes in one area are reflected instantly across related departments.

- Planners can simulate scenarios before committing to schedules.

Practical Impact:

- Fewer last-minute schedule changes.

- Better equipment utilization.

- Reduced idle time caused by missing inputs.

Inventory and Supply Chain Optimization

Inventory issues are one of the most common causes of production stoppages.

ERP provides:

- Real-time stock visibility across warehouses and plants.

- Automated reorder triggers based on demand and lead times.

- Support for Just-in-Time models where suitable.

Industry studies show ERP-driven inventory optimization can reduce excess and shortage-related issues by 20 to 40 percent, depending on process maturity.

Practical Impact:

- Fewer line stoppages due to material shortages.

- Lower carrying costs.

- Improved cash flow.

Quality Control and Compliance Built into Workflows

Quality issues discovered late are expensive. ERP embeds quality checks into production processes.

- Inspections are tracked from incoming materials to finished goods.

- Non-conformances trigger corrective actions automatically.

- Full traceability supports audits and compliance requirements.

Practical Impact:

- Faster root cause analysis.

- Less rework and scrap.

- More consistent product quality.

IoT Integration and Predictive Maintenance

Unplanned downtime is one of the costliest bottlenecks in manufacturing.

ERP systems integrated with IoT sensors can:

- Monitor machine conditions such as vibration, temperature, and runtime.

- Predict failures before breakdowns occur.

- Align maintenance schedules with production plans.

Practical Impact:

- Reduced unexpected downtime.

- Longer equipment life.

- Better coordination between maintenance and production teams.

Data-driven Decisions with Real-time Dashboards

ERP dashboards give managers instant access to critical KPIs.

Common metrics include:

- Overall Equipment Effectiveness (OEE).

- Schedule adherence.

- Inventory turnover and stockout rates.

- First-pass yield and defect rates.

- On-time, in-full delivery performance.

Practical Impact:

- Bottlenecks are identified early.

- Decisions are made faster.

- Continuous improvement becomes measurable.

Tangible Benefits Manufacturers See After ERP Adoption

| Outcome | Realistic Expectation | Why It Happens |

|---|---|---|

| Lead Time Reduction | 25% to 95% | Automated scheduling, elimination of “white space” between departments. |

| Inventory Cost Reduction | Up to 75% | Just-In-Time (JIT) ordering, reduction of dead/obsolete stock. |

| Operational Costs | ~23% Decrease | Automation of manual data entry and administrative tasks. |

| Productivity Gains | ~30% Increase | Staff focus on value-added work instead of chasing paper. |

These outcomes depend on disciplined implementation and adoption, not just software features.

Implementing ERP Without Disrupting Production

Start with a Phased Rollout

A phased approach reduces risk and allows for gradual adaptation.- Begin with high-impact modules such as production planning, inventory, and procurement.

- Define success metrics for each phase.

- Stabilize before expanding to advanced capabilities.

Focus on People and Training

ERP success depends on user adoption more than technology features.

- Provide role-based training instead of generic sessions.

- Show teams how ERP reduces daily friction.

- Involve supervisors and planners early in the process.

Clean Data and Integration Planning

ERP will expose poor data quality if not addressed upfront.

- Clean item masters, BOMs, routings, and supplier records.

- Plan integrations with MES, PLM, barcode systems, and IoT platforms.

- Test thoroughly before go-live to ensure smooth transition.

How to Choose the Right ERP for Your Manufacturing Business

When evaluating ERP systems, manufacturers should focus on:

Fit with manufacturing type: Discrete, process, or mixed-mode manufacturing requirements.

Core capabilities:

- MRP and capacity planning

- BOM and routing management

- Lot and serial traceability

- Cost tracking and reporting

Ease of use and vendor support: Intuitive interface and reliable implementation support.

Scalability for future growth: Ability to expand with your business needs.

Remember: Technology should support operations, not complicate them. The right ERP should feel like a natural extension of your manufacturing processes.

Cloud vs On-Premise ERP for Manufacturing

Choosing the right deployment model matters for your manufacturing operations.

Cloud ERP

- Faster deployment and easier scaling

- Access from multiple locations

- Lower infrastructure management effort

On-Premise ERP

- Greater control over internal systems

- Preferred in high-control environments

- Higher responsibility for maintenance

Hybrid ERP

- Combines local control with cloud flexibility

- Useful for phased modernization

- Balanced approach for complex needs

Decision factors should include compliance needs, shop floor latency, IT capacity, and total cost of ownership.

Frequently Asked Questions

How does ERP improve OEE (Overall Equipment Effectiveness)?

ERP identifies downtime causes, aligns maintenance with production, and improves schedule adherence, all of which directly contribute to higher OEE metrics.

Can ERP reduce downtime without new machines?

Yes. Better planning, predictive maintenance, and real-time visibility reduce idle time and breakdowns without requiring capital investment in new machinery.

How soon can ROI be measured after ERP implementation?

Many manufacturers see measurable improvements within 6 to 12 months, depending on the scope of implementation and level of adoption across the organization.

Is cloud ERP secure for sensitive manufacturing data?

Modern cloud ERP platforms use strong encryption, multi-factor authentication, access controls, and compliance frameworks (like ISO 27001) to ensure data security exceeds what most manufacturers can achieve on-premise.

Move From Firefighting to Controlled Execution

Manufacturing bottlenecks are rarely isolated problems. They are signals of disconnected processes and delayed information. ERP addresses these root causes by bringing visibility, structure, and automation into daily operations.

For manufacturers aiming to scale, improve margins, and deliver consistently, ERP is no longer optional. It is the foundation for precision-driven manufacturing.