Unlocking Efficiency in Workshop Operations

This document discusses the challenges of vehicle downtime and service delays in automotive and machinery workshops in Bahrain and the GCC, and how Workshop Management ERP systems can address these issues. By centralizing operations and providing real-time insights, these powerful solutions transform chaotic manual processes into streamlined, profitable workflow

The Downtime Dilemma

Manual Job Cards and Paper-Based Tracking:

Leads to lost or misplaced documents, illegible handwriting, lack of immediate job status overview, and difficulty in tracking costs, resulting in delays.

Profitability:

Missed delivery timelines, increased labor costs (rework, overtime), and reduced revenue directly impact the bottom line.

Poor Technician Scheduling:

Inefficient scheduling leads to technicians being idle or overwhelmed, bottlenecks, and delays in job completion due to mismatched skills or overloaded senior technicians.

Customer Trust:

Dissatisfaction, loss of future business, and negative word-of-mouth reputation can severely damage a workshop's standing.

Spare Parts Unavailability and Inventory Gaps:

Crucial components being out of stock pauses jobs. Lack of automated alerts or clear inventory views prevents proactive reordering and job planning based on availability.

Workshop Throughput:

Reduced overall capacity and efficiency directly hinder the workshop's ability to handle service volumes.

Lack of Real-Time Service Status:

Reliance on manual follow-ups for job progress leads to distractions for technicians and vague updates for customers, eroding trust.

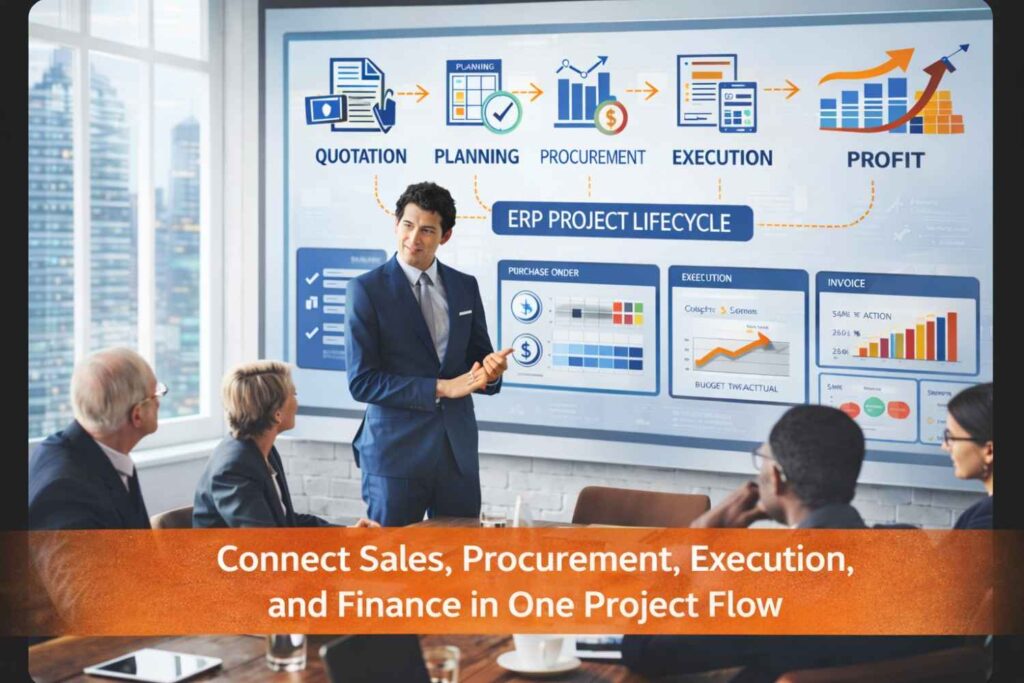

Introducing Workshop Management ERP

A Workshop Management ERP (Enterprise Resource Planning) is a powerful software solution that integrates and automates all key operational aspects of a service business. It acts as a central system, pulling together data from jobs, technicians, inventory, customer details, and billing into a single, unified database.

Specifically tailored for automotive and machinery service workflows, an ERP provides a holistic view and control over your entire workshop, transforming fragmented processes into cohesive, efficient operations.

ERP: Your Solution to Delays

Centralized Job Card & Work Order Management

Digital job cards replace paper, ensuring clear priority and timelines. Technicians get instant access to history, notes, and parts, minimizing handover delays.

Smart Technician Scheduling & Workload Balancing

Assigns jobs based on skill and availability, reducing idle time and enabling seamless transitions between tasks for optimal efficiency.

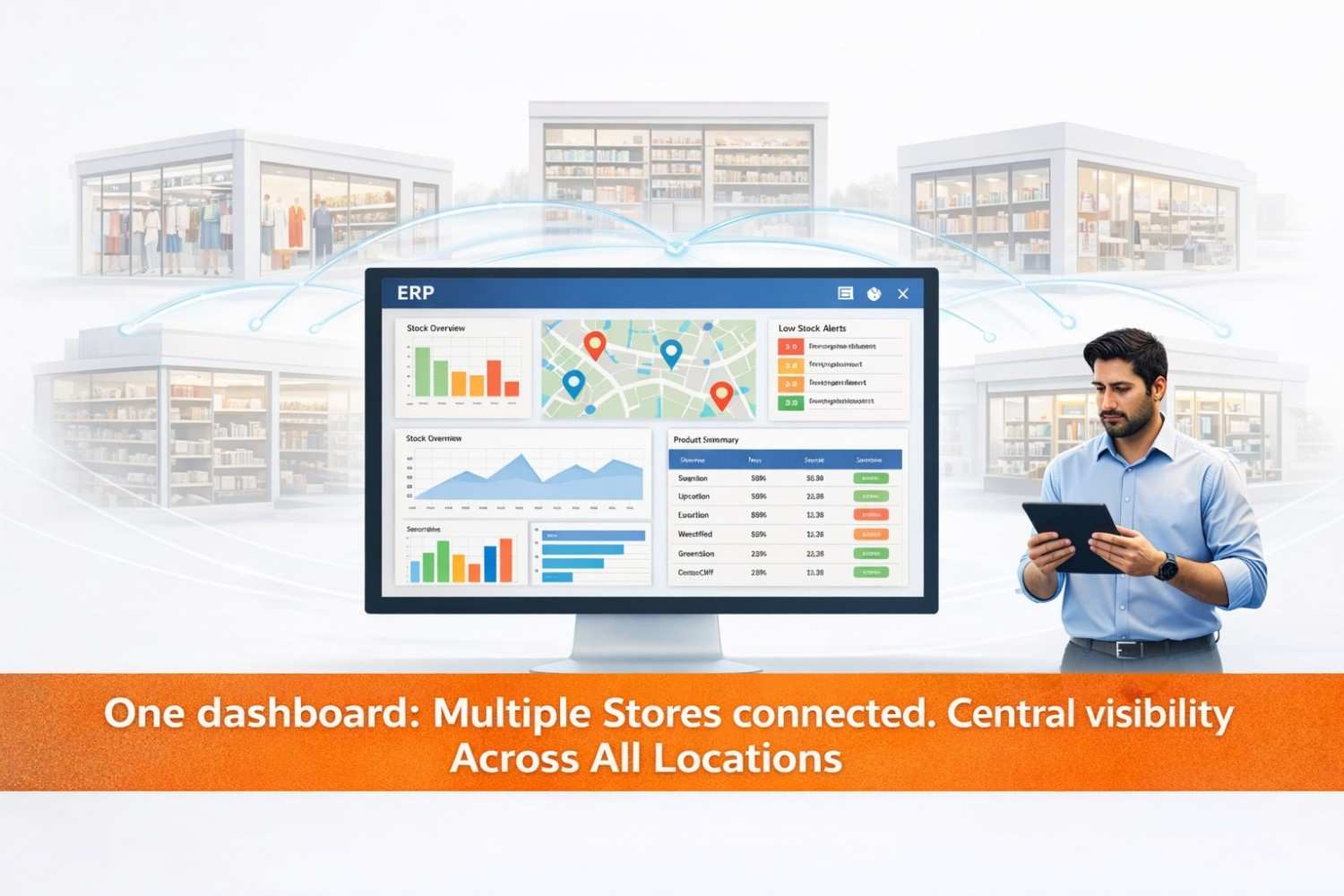

Real-Time Service Tracking for Managers

Interactive dashboards provide live visibility into all ongoing jobs, enabling early identification of bottlenecks for proactive intervention.

Integrated Spare Parts & Inventory Management

Auto-alerts for low stock, prompting timely reorders. Job planning based on confirmed parts availability avoids unnecessary downtime.

Preventive Maintenance Planning

Enables scheduling maintenance before breakdowns based on usage, mileage, or time, significantly reducing emergency disruptions.

ERP Benefits for Automotive Workshops in Bahrain & GCC

Faster turnaround during peak periods, better coordination across multi-branch workshops, improved compliance and documentation, and scalable operations that support sustainable growth.

Before vs. After ERP: A Real-World Transformation

Before ERP: Manual Maze

Paper Job Cards:

Prone to loss, illegibility, and difficult tracking, causing significant delays.

Manual Part Checks:

Slow, error-prone, leading to discovery of missing parts mid-job and extended downtimes.

Vague Customer Updates:

Reliance on manual follow-ups leads to customer dissatisfaction and eroded trust.

Occupied Bays & Technician Reassignment:

Inefficient resource utilization and constant re-planning disrupt workflow.

After ERP: Precision & Predictability

Digital Job Cards:

Instant access, clear priorities, and complete service history for every job.

Automated Customer Updates:

Proactive notifications and accurate estimated completion times improve confidence.

Immediate Inventory Checks:

Automated alerts for low stock and parts availability confirmed before job assignment.

Optimized Bay Utilization:

Intelligent scheduling minimizes bay idle time and technician overload, boosting throughput.

Key ERP Features & Scalability

Job Card & Service Workflow Automation

Automates the entire service lifecycle from booking to billing.

Technician Scheduling & Productivity Tracking

Intelligent scheduling based on skills, availability, and real-time job tracking.

Spare Parts & Inventory Control

Real-time stock visibility, automated reorder alerts, and parts usage tracking.

Asset & Maintenance Management

Tracks equipment history, schedules preventive maintenance, and monitors performance.

Real-Time Dashboards & Reports

Customizable dashboards for KPIs, live job status, productivity, and bottleneck identification.

Cloud-Based Access for Managers

Allows managers to access and oversee operations from anywhere, anytime, enhancing flexibility.

Suitability for Small and Mid-Sized Workshops (SMEs)

Modern ERP systems are highly scalable and flexible, often offering modular components. This means SMEs can implement only the necessary features initially and seamlessly expand as their business grows.

The benefits, such as increased efficiency, reduced errors, and enhanced decision-making, translate to a faster and substantial Return on Investment (ROI) for SMEs.

Choosing the Right ERP Implementation Partner in Bahrain

Local Expertise:

Look for ERP implementation partner in Bahrain with deep local understanding and specific industry expertise in automotive and machinery service workflows. with deep local understanding and specific industry expertise in automotive and machinery service workflows.

Customizable Solutions:

Ensure they offer adaptable ERP solutions that can be tailored to your unique workshop needs.

Comprehensive Support:

Prioritize partners providing thorough training, ongoing support, and proven local implementation experience.

The Future of Workshop Efficiency

Implementing a Workshop Management ERP system replaces fragmented processes with integrated, automated workflows, providing structure, real-time visibility, and predictability. This transforms workshops into proactive, highly efficient operations, reducing downtime and laying a foundation for sustainable growth and profitability. Solutions like Hornet Technologies ERP offer customizable platforms tailored to specific needs, empowering your business to thrive in the competitive GCC market.