Construction budgets rarely fail overnight. They slip little by little. A missed material entry. A late procurement approval. A small measurement error. By the time project owners and contractors notice the pattern, margins are already gone.

If you build residential towers, villas, commercial spaces or industrial projects, you know how easy it is for costs to drift without warning. And the biggest reason is simple. The data you need to control costs is scattered everywhere.

This is where a Construction ERP Software acts like your “control tower”, helping contractors and developers track every activity, every material and every rupee spent. Let’s break it down in a simple way.

Table of Contents

Why Construction Budgets Go Off Track

Cost overruns are usually not caused by one big issue. They accumulate from many small and unmanaged gaps.

- Inaccurate or outdated project estimates – Estimations are often done on spreadsheets or old BOQs. Without historical cost data and rate benchmarks, estimates become unrealistic.

- Scope changes without financial impact tracking – Variations happen. But when they are not mapped immediately to cost and timeline, projects drift.

- Delayed manual procurement – Price fluctuations, duplicate orders, last-minute purchases and supplier delays create financial leakage.

- Poor on-site material monitoring – Materials reach the site. But real consumption is often not recorded in real time. This results in wastage, pilferage and mismatch with the BOQ.

- Fragmented reporting – Every team uses its own tool. Finance, site engineers, supervisors and procurement teams never see the same data.

Together, these gaps pull the project away from your target cost.

The Real-World Impact of Construction Cost Overruns

Contractors often underestimate how severely overruns affect long-term profitability. Here are credible, recent industry statistics.

Key Global Construction Cost Overrun Statistics

80%

Cost OverrunLarge construction projects run up to 80% over budget.

McKinsey & Company (Imagining Construction’s Digital Future)

98%

Megaproject OverrunsMegaprojects experience major cost overruns.

McKinsey Global Institute, The Construction Productivity Imperative

50%+

Underperforming ProjectsOver half of engineering & construction firms report underperforming projects.

14%

Rework From Bad DataOf global construction rework is caused by bad data.

These numbers clearly show why budget deviations are a systemic issue, not an isolated one.

How These Overruns Affect Contractors and Developers

Reduced Profit Margins

When material wastage or price hikes are detected late, contractors lose profits even if the project is delivered successfully.

Delayed Payments and Cash Flow Stress

Variation claims, inaccurate invoicing and slow documentation impact cash flow. This affects salaries, supplier payments and site progress.

Damaged Client Trust

Missed deadlines and unexpected cost escalations make clients lose confidence. This affects future recommendations and tender eligibility.

Loss of Future Tenders

Government and private sector prequalification often evaluates contractors based on historical cost performance.

Operational Firefighting

Instead of planning ahead, teams end up reacting to daily issues. Productivity drops and mistakes increase.

This is why most contractors are now shifting to

Construction ERP Software.

Learn How Hornet Technologies can help with Construction Industry Software Implementation & Integration

Where Construction ERP Software Fits In

A Construction ERP brings everything into one place. Planning, materials, procurement, finance, labour, equipment and reporting. That means no more blind spots.

1. Real-time Project Cost Tracking

You can see estimated cost vs actual cost instantly. When a cost crosses its limit, the system alerts you.2. BOQ-Linked Estimation

BOQs become live documents. Any change in quantity or rate is reflected across procurement, inventory and finance.3. Material Tracking Across Every Site

Materials are logged as soon as they enter and leave the site. You get visibility of stock, consumption, wastage and transfers.4. Smart Procurement

Compare vendor prices, track pending POs, automate approvals and lock rates to avoid surprises.5. Centralized Dashboards

Project managers, accountants and owners get dashboards tailored to their roles.How Hornet’s ERP Helps Construction Firms Stay Within Budget

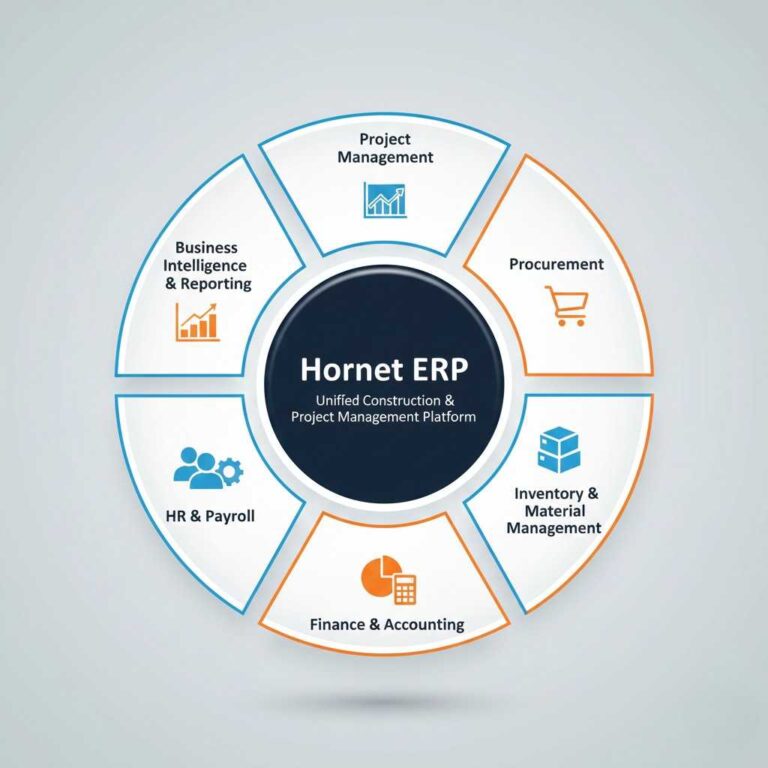

Hornet ERP is designed to remove the exact issues that create cost overruns in construction projects. It connects your BOQs, materials, labour, tasks and finances in real time.

- Project Planning and Budget Control

- Procurement and Purchase Automation

- Material and Inventory Tracking

- Finance and Accounting Integration

- Project-Based Reporting and BI

Project-wise P&L, budget tracking and financial visibility.

Real-time dashboards for quick cost analysis.

Task-level allocation and monitoring.

Supplier quotations, comparison, approvals and PO automation.

Landed cost calculation for accurate costing.

Integrated vendor history and pending delivery tracking.

Multi-warehouse stock visibility.

Batch and serial number tracking.

Real-time stock entry, issue and consumption logs.

Site-level stock tracking and alerts for shortages.

Accurate costing, cash flow, general ledger, P&L and statutory reports.

Multi-currency and automated financial workflows.

Bank reconciliation, vendor payments, PDC tracking and more.

Consolidated dashboards.

Project progress vs budget.

Multi-branch reporting for groups handling multiple projects.

Benefits of Implementing a Construction ERP

Better forecasting. You know future cash needs, material requirements and labour demands.

Lower material wastage. Consumption vs BOQ is monitored continuously.

Faster execution with fewer delays.

Higher transparency across vendors, supervisors and owners.

Improved profit margins because leakages are spotted early.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

The Future of Construction Cost Monitoring

Construction firms are moving towards digital workflows, predictive tools and AI-supported planning.

AI-Based Forecasting

Predict future cost overruns and delays before they happen.

IoT Sensors

Monitor material movement at large construction sites in real-time.

Mobile-First Monitoring

Supervisors log activities instantly from the field.

Digital Twins

Simulate cost impact before construction begins.

Why Hornet Technologies Is a Reliable ERP Partner?

10+

Years of Experience

250+

Successful Projects

24/7

Dedicated Support

10+ years of implementation experience

Industry-ready modules

250+ successful projects

Cloud, on-premise and hybrid deployment

Dedicated support and training teams

Conclusion

Construction projects don’t go over budget because teams lack skill. They go over budget because teams lack visibility. When data is scattered, decisions get delayed. When decisions get delayed, costs rise.

A ERP implementation & Integration provider like Hornet gives contractors the clarity, accuracy and control needed to deliver projects profitably. With connected BOQs, materials, finance and procurement, managing project costs becomes simpler and far more predictable.

If you want to reduce cost overruns and get real-time control over your projects, this may be your best next step.

FAQs

Do most construction firms actually use ERP systems — or do many still rely on spreadsheets and basic tools?

Many users report that even large firms sometimes avoid full ERP, citing complexity, manual data entry, or cost

What real benefits do construction-specific ERPs bring compared to generic project-management tools?

Reddit threads highlight advantages like consolidated procurement, inventory tracking, project-wise cost control, and automation that spreadsheets alone cannot handle.

Is ERP worth it for small or mid-size contractors, or only for large firms with many projects?

Several subreddit commenters caution that unless your firm crosses a certain scale (multiple projects, many sites), the complexity and cost of ERP may not pay off — for smaller firms, spreadsheets or basic tools may be more cost-effective.

What are the common obstacles or challenges when implementing ERP in a construction firm?

Users often mention issues like data entry burden, resistance to change among staff, integration complexity, and delayed ROI — especially if the firm lacks clean data and process discipline.

Can ERP systems adapt to construction-specific workflows (like project-wise costing, change orders, multiple sites)?

Yes — many posts point out that modern ERPs designed for construction can handle project-wise cost tracking, inventory across sites, vendor management, and more — but only if properly configured and used consistently.

Is it realistic to expect full automation with ERP, or will manual data entry always remain a bottleneck?

A recurring concern from users is that ERP’s effectiveness still depends heavily on accurate and timely data entry. Automation helps, but garbage in will still lead to garbage out