Running a restaurant is not just about increasing sales. It is about protecting margins, controlling waste, and ensuring operations run without friction.

Many cafés, QSRs, and multi-branch restaurants see strong daily sales. Yet profits remain inconsistent.

The reason is often not demand. It is system disconnect.

When POS, kitchen, inventory, and finance operate separately, small gaps become daily losses.

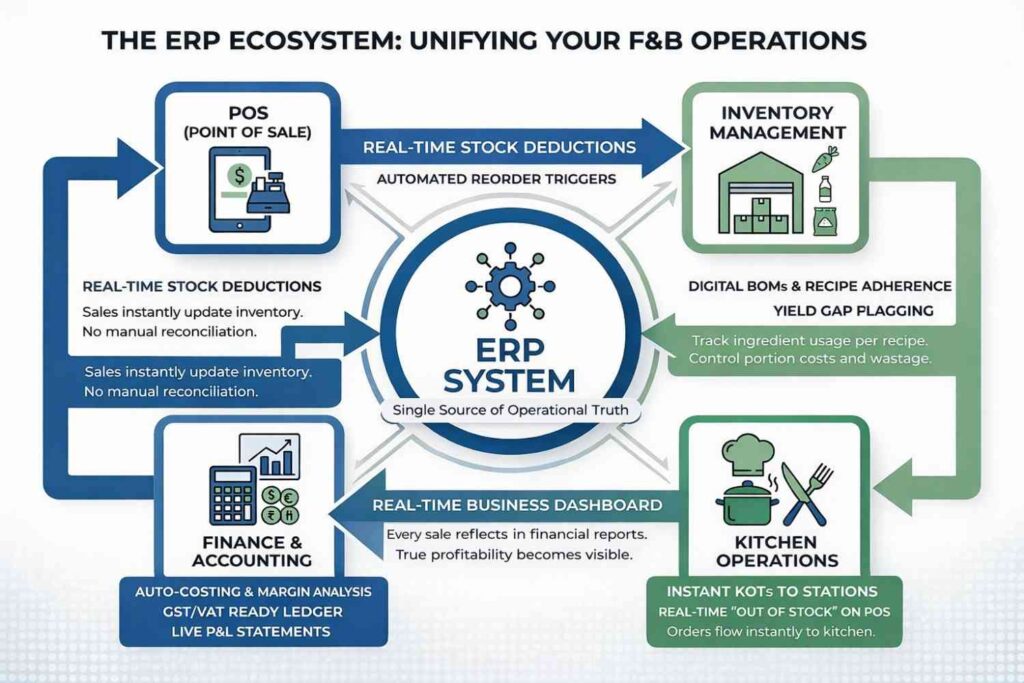

An integrated Restaurant ERP connects these functions into one controlled flow. One version of the truth.

The Industry Is Moving Toward Integrated ERP

The shift toward connected ERP systems is not a trend. It is a structural shift in the industry.

$3.6B

2023 MARKET VALUE

$6.4B

2030 Projected

8.5%

CAGR

According to Virtue Market Research, the Global Food & Beverage ERP Solution Market was valued at USD 3.6 billion in 2023 and is projected to reach USD 6.4 billion by 2030, growing at a CAGR of 8.5 percent. This growth reflects rising operational complexity, stricter compliance demands, and the need for real-time visibility across inventory, production, and finance.

F&B businesses are investing in ERP because manual processes no longer scale.

What Breaks When Systems Are Disconnected

If you run a restaurant, you may recognize these situations:

POS shows strong revenue, but food cost keeps rising.

Sales data doesn't talk to inventory — so cost increases stay invisible until month end.

Kitchen runs out of ingredients even when stock shows available.

Inventory reflects what was bought, not what was used per recipe. Disconnect hides real consumption.

Waste is happening, but it is not measurable.

Without integrated waste logging, spoilage doesn't impact food cost — until it's too late.

Month-end reconciliation takes days.

Manual matching between POS, purchases, and finance creates endless overtime.

These are not staff issues. They are system gaps.

Without integration: sales data does not match inventory movement; inventory does not reflect kitchen reality; finance does not see real cost in real time.

The ERP Connection Flow Inside a Restaurant

Let us walk through a real scenario. It is Friday evening. Orders spike.

Inside an integrated ERP system:

- Customer places an order at POS.

- Kitchen Order Ticket (KOT) generated instantly.

- Ingredients deduct automatically from inventory.

- Stock drops → reorder alerts.

- Sales & stock post directly into finance.

- Dashboards update revenue, cost, margin in real time.

No manual adjustment. No double entry. No surprises at closing.

POS Meets Inventory. Real-Time Stock Control

This is where POS software integration becomes critical for real-time stock accuracy.

Ingredient Deduction Per Dish

Every menu item is mapped to a digital recipe. When a dish is sold: exact ingredient quantities deduct automatically; stock updates immediately; variances become visible. This prevents the classic issue: “Stock report looked fine. Kitchen ran out.”

Auto Reorder for Perishables

Minimum and maximum levels can be defined per ingredient. When thresholds are hit: the system alerts purchasing, or generates purchase requests. This prevents rush-hour shortages, overstock of short shelf-life ingredients, and emergency buying at higher prices.

Waste Logging That Impacts Financial Reports

Spoilage and prep loss can be recorded directly in the system. When wastage is logged: inventory reduces, food cost updates, financial reports reflect actual consumption. Waste stops being invisible.

Virtue Market Research notes that inventory management functionality represents over 35% of the Food & Beverage ERP market, highlighting how critical stock control is for modern F&B operations.

Inventory Powers the Kitchen. Recipe and Yield Control

Kitchen efficiency depends on ingredient accuracy. A connected inventory management system ensures ingredients deduct automatically per sale.

-

Digital Recipes

-

Yield Variance

-

Batch and Expiry

Digital Recipes as Bills of Materials: Each dish includes defined ingredients, defined quantities, standardized portions. This ensures consistent taste, controlled food cost, predictable margins.

Yield Variance Tracking: The system compares expected ingredient usage vs actual consumption. If variance is high, it flags over-portioning, process inefficiencies, or possible stock leakage. Small daily improvements compound into major cost savings.

Batch and Expiry Tracking: For central kitchens and multi-location operations, expiry dates can be tracked, batch movement monitored, recall readiness improved. Traceability is not optional in F&B. It is essential. Traceability improves both compliance and operational agility.

According to an Aberdeen report on ERP effectiveness in F&B , Best-in-Class companies are 62% more likely to have traceability of components and items throughout purchasing, manufacturing, and sales processes.

Kitchen Flows Back to POS. Live Synchronization

Integration works both ways.

Instant KOT Sync – Orders move instantly from POS to kitchen display, reducing relay errors, missed tickets, service delays.

Live Menu Availability – If ingredient unavailable, item blocked at POS; staff alerted before confirming orders.

Menu Engineering with Real Data – ERP connects sales trends, ingredient cost, margin performance. Identify high-selling low-margin dishes, waste items.

Finance Ties Everything Together

This is where ERP changes decision-making.

Automated Posting and Faster Closing

Sales, purchases, stock adjustments, and waste entries post directly into finance. This reduces manual reconciliation, ledger mismatches, month-end pressure.

Real-Time Margin Visibility

Instead of estimating food cost, you can see item-wise profitability, category-level margins, outlet-wise performance comparison. Aberdeen research shows that Best-in-Class F&B companies report a 6.6% improvement in profitability over two years, while others experienced decline. Integrated ERP visibility is a key driver of that performance gap.

Compliance and Audit Readiness

With connected systems: purchase orders match GRNs; sales match revenue; traceability logs remain intact. Compliance becomes structured, not reactive.

Stop system disconnect. Start controlling margins.

See how Hornet ERP gives you real-time visibility from POS to finance.

What Changes When You Run on One Integrated ERP

Operational Gains – Fewer stockouts, lower wastage, faster service, better supplier coordination.

Management Clarity – Multi-branch dashboards, real-time sales/cost visibility, data-driven forecasting, controlled expansion.

Growth becomes measurable.

Why Integration Matters for Cafés and Chains

Integrated ERP benefits: single-outlet cafés, QSR formats, cloud kitchens, multi-location restaurant chains, central kitchens. You can begin with POS and inventory. Then extend to finance, procurement, and multi-branch reporting. ERP scales as you grow.

How Restaurants Implement ERP Successfully

A structured rollout minimizes disruption: 1. Assess operational gaps. 2. Map recipes, workflows, and approval controls. 3. Train teams by role. 4. Go live in phases. When implemented correctly, ERP reduces chaos instead of adding complexity.

Final Takeaway

Sales do not automatically mean profit. Control drives profit. When POS, kitchen, inventory, and finance operate inside one connected ERP flow: stock reflects reality, margins become visible, decisions become data-driven, growth becomes structured.

If your restaurant’s sales look strong but profits feel unclear, the issue may not be demand. It may be system disconnect.

Hornet Technologies helps F&B businesses in GCC & Bahrain by bringing their operations into one integrated system designed for real operational visibility and financial clarity.

Better growth starts with better control.